The In-Laws have just moved house. I say move house, but what I mean is sold their old self-build, bought a field in deepest darkest Norfolk and are planning to self-build again. This is great news because it means they’ve got a blank canvas to fill with numerous eco-build projects. The first of which is a criminal deterent. I’m sure the working ip-camera will be used at some point but until then a decoy camera will have to suffice. Decoy cameras work fine so long at they remain believable, and so this decoy camera needs that little extra bit of polish; a flashing LED.

The flashing LED project is the “Hello World” for those whose programming language is solder. Any time you learn a new microcontroller, you will face the flashing LED tutorial. This is designed so that you can set up all the important registers and interface with the outside world. When you talk about flashing LED projects without using a mcu, people will generally offer the 555 timer as a solution. I’m going to look at three options, and hopefully have a working flashing light at the end.

The main design considerations are the need for a long battery life, and a fairly cheap design. I’m going to be using the LPKF Protomat C60 at work to cut the board out, and I’ll be trying to use components I have in my bits box, or can get free samples of. I am aiming for the design to fit on the back of my selected battery solution, and have a suitable mounting fixture integrated into the PCB design.

I know I need to use battery power, and once installed the batteries can’t really be changed. The build should take 2 years, and so I am aiming for more than that. I’m going to overengineer this aspect horendiously as my professional integrety is at stake. Obviously, a car battery would be a rediculous solution, and although space is not at a premium I’d still like to make the package small. My options consist of a single PP3 battery, a single CR2032, or a pair of AA batteries. The CR2032 only has a capacity of around 200mAh, with the PP3 only doubling that. The AA has to be the victor at well over 1000mAh. Thankfully, the AA battery holder is a also almost half the cost of a CR2032 holder. Lastly, is the actual flashing LED. A flashing light project without a flashing light simply isn’t. The minimum current draw I can reasonably expect to look at is 1mA. Any lower and I dont think the LED would be bright enough to see at a distance. The human visual cortex holds onto an image for about 1/15s, or approx 66ms, so I think that 100ms is a reasonable on time for the circuit.

I’ve mentioned the 555 timer as a possible solution so lets examine that a bit closer. Normally, the 555 doesn’t output a duty cycle of less that 50% which is bad for a low power design. The duty cycle issue can be addressed with a 1N4148 in parallel with the resistor between the discharge and trigger pins. Alternatively, you can reverse the LED and connect to Vdd instead of Vss, sinking current through the 555. The ICM7555 is Maxim’s low power derivative of the 555, having a typical supply current of 60uA. Assuming a battery capacity of 1000mAh, the 555 would run for 16666.67 hours (a month less than 2 years) without flashing an LED. The 555 just doesn’t cut it.

The next obvious solution would be a low power microcontroller. This is great as the LED can do more than just flash. It can reverse bias the LED to work as a light detection circuit, and the LED can do a double flash for extra realism. The PIC18LF13K22 has a low power sleep current consumption of only 460nA. This would be 34nA but I need to keep a timer running to wake the thing up. Even a draw of 460nA gives a run time of 248 years on a 1000mA battery, which is just crazy. Adding the LED gives a battery life of 5 and a half years. With a BOM of only 5 components this ticks every box, but using a microcontroller feels like cheating. I think this will be my backup plan if the next idea falls through.

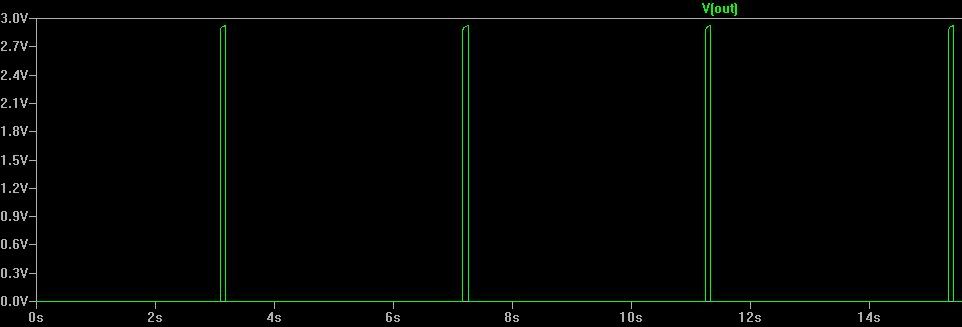

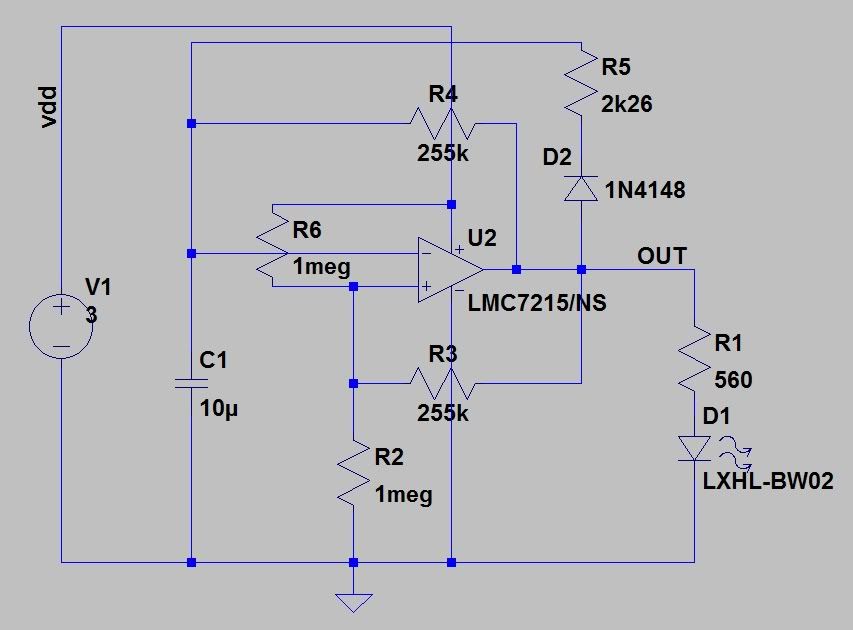

My final option is an op-amp. The op-amp in question is Linear Technology’s LMC7215. By using positive and negative feedback and a crafty 1N4148, the LMC7215 can be made to oscillate with a definable peroid and duty cycle. I used LTSpice to simulate the actual circuit and can extract the predicted current draw (tutorial to follow), giving a battery life of just over 5 years. Using my parts box, I managed to get a on-time of 92ms, and a period of 4 seconds.

The op-amp circuit does give a higher parts count, but this still ticks every box, and I think it is more elegant than the PIC solution. Next article, I will be showing how to use LTSpice to come up with the appropriate values, and importing SPICE definitions into the circuit. I will also lay out the PCB in CAD, and start the enclosure design. See you then.